Technical preparation

We believe that the basis of any successful production is quality technical preparation. To ensure the best possible care for your order, we have a department with a team of experienced employees to carefully prepare individual orders. From setting up the technological procedures of production, through meticulous control and processing of data documents in our own graphic and DTP studio,including 3D visualization of the packaging before production, to CTP illumination and final inspection of the printing plates.

Colour Management

Colour management in our company starts with the DTP studio, continues through our own studio for digitally controlled colour mixing and the approved colour is finally checked by densitometric and spectral measurement. This makes it possible for us to guarantee a faithful colour reproduction with a deviation that meets the latest standards for quality offset printing and repeat production.

Offset printing

We use offset printing on sheets with up to six colours per pass using conventional or UV colours, including the option of printing in white. Thanks to the two additional varnishing units that are part of the printing machines, we can also add special finishes using dispersion or UV varnishes in one process. This allows us to achieve high productivity with variable print finishing options, print accuracy and superior output quality.

The most commonly used material is plain cardboard, but we also process many other types of paper. And thanks to our corona unit, we can even print on non‑absorbent materials.

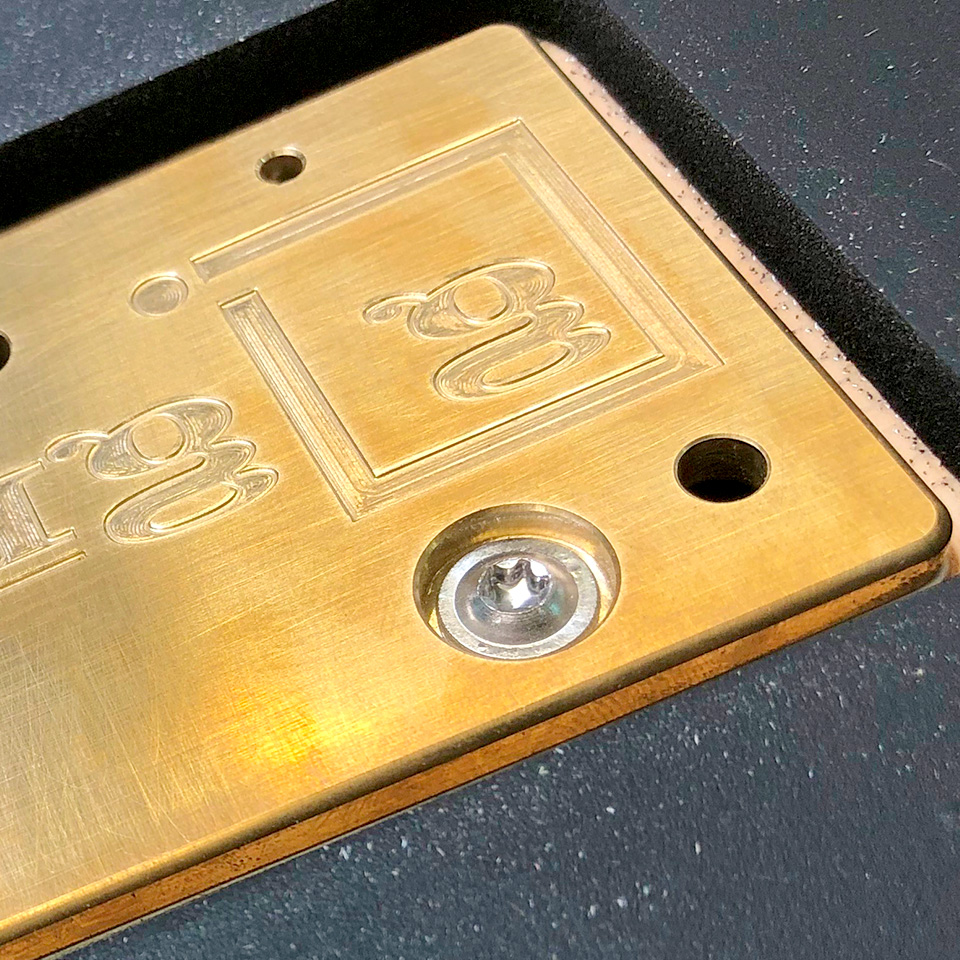

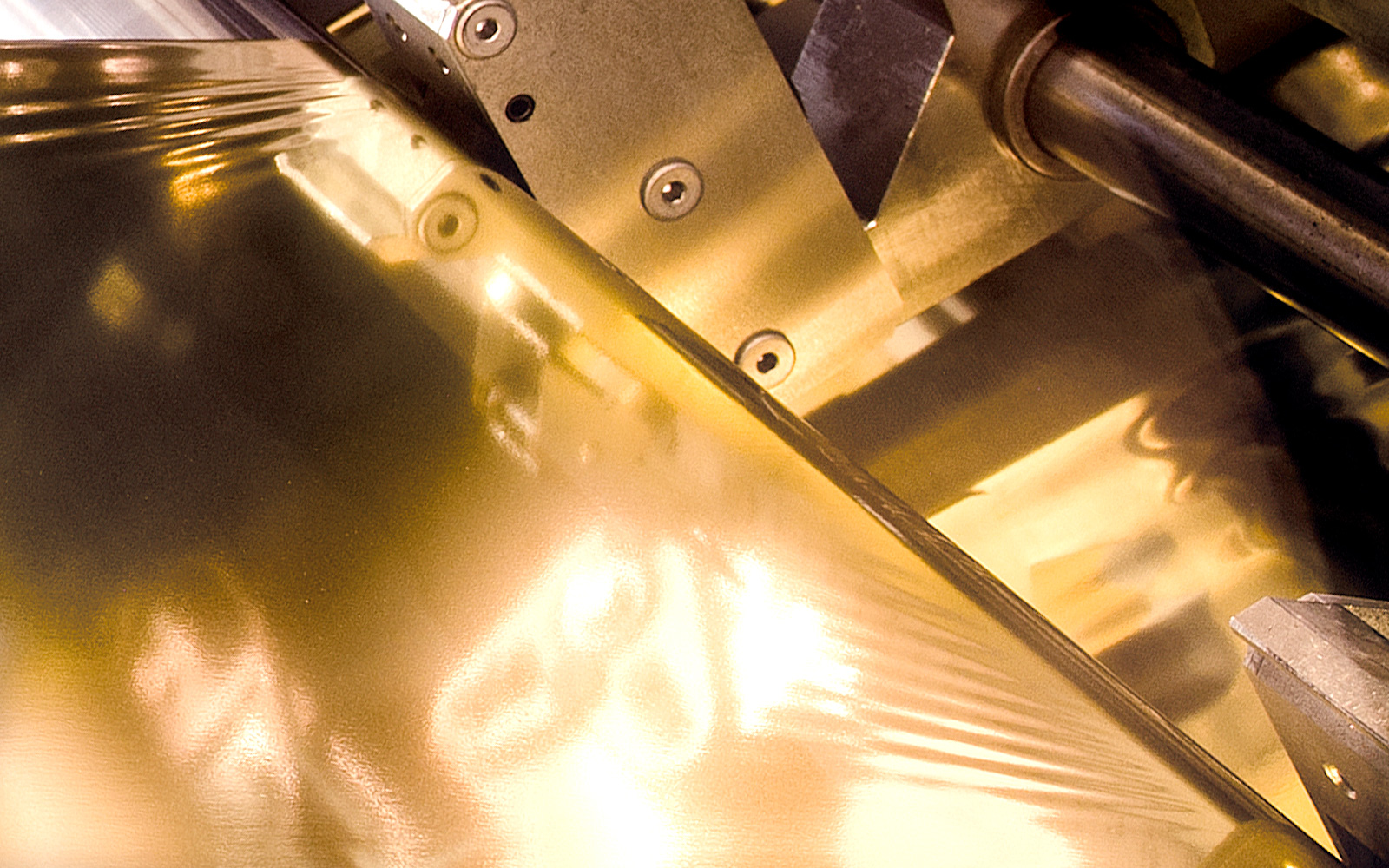

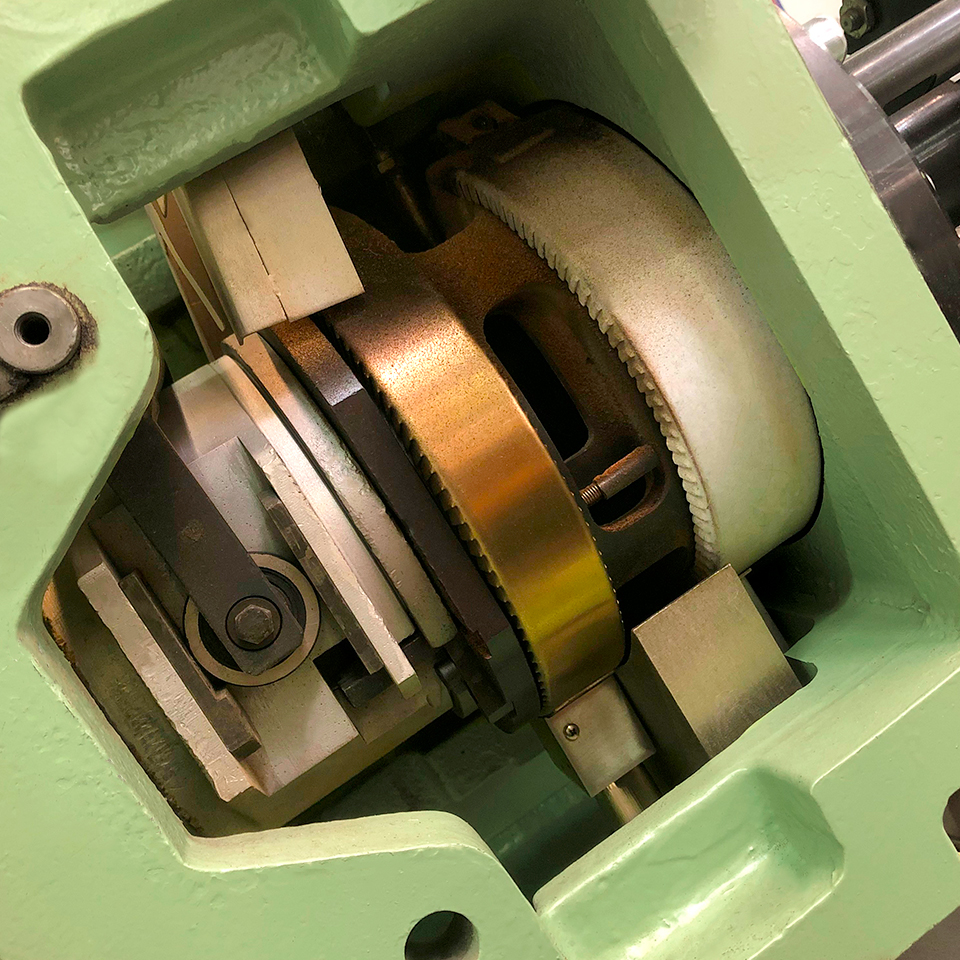

Hot Foil Stamping and Embossing

One of the more luxurious finishing techniques used or boxes and printed matter is the application of metallic foils by hot stamping.

Gold and silver are the most desirable, but there is a whole range of colours and finishes on offer, including special finishes such as diffraction or holographic foils.

Embossing is another packaging finishing method. This will literally allow your design to stand out. This technology is mainly used in packaging for branded alcohol, chocolate bars, desserts, cosmetics and gift items.

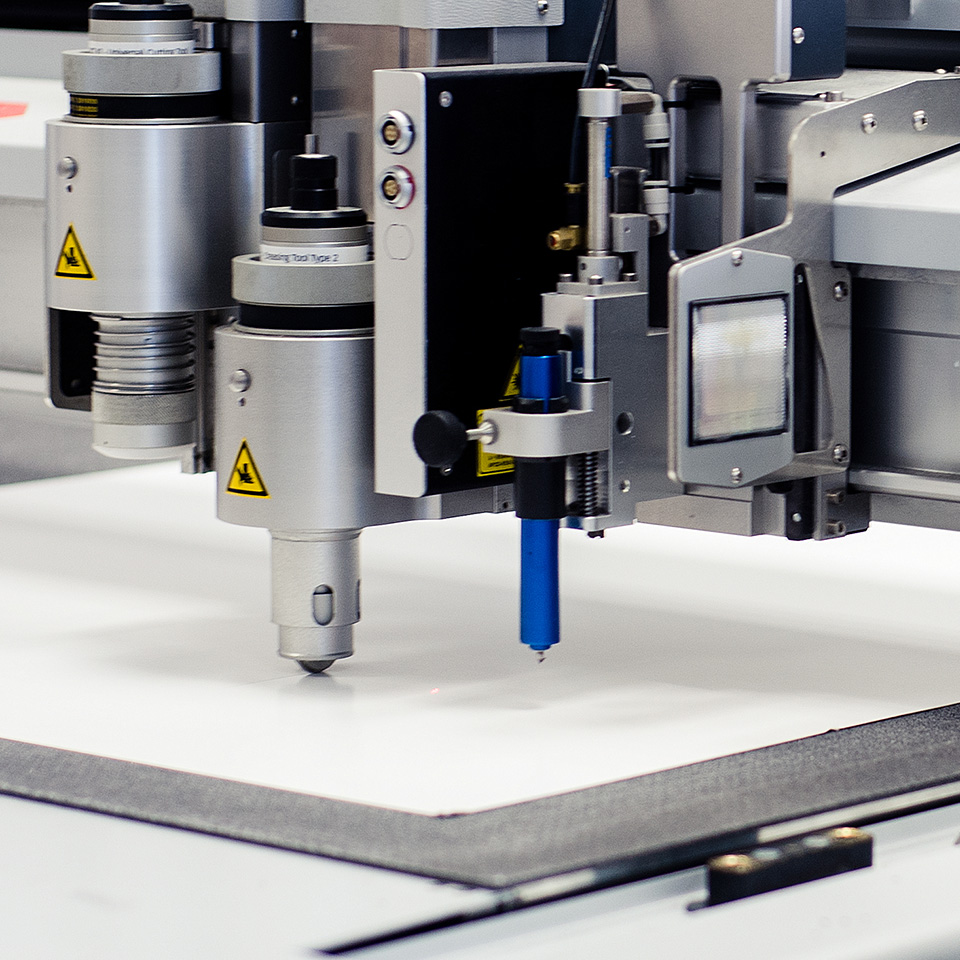

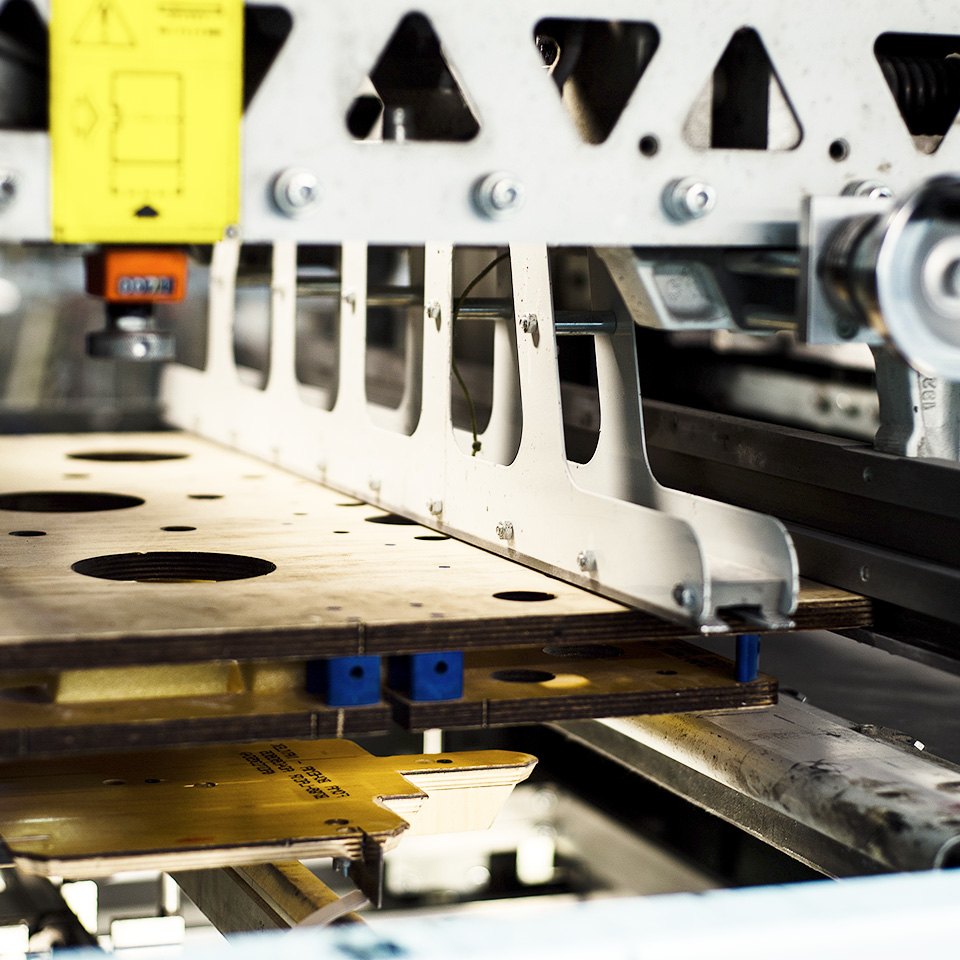

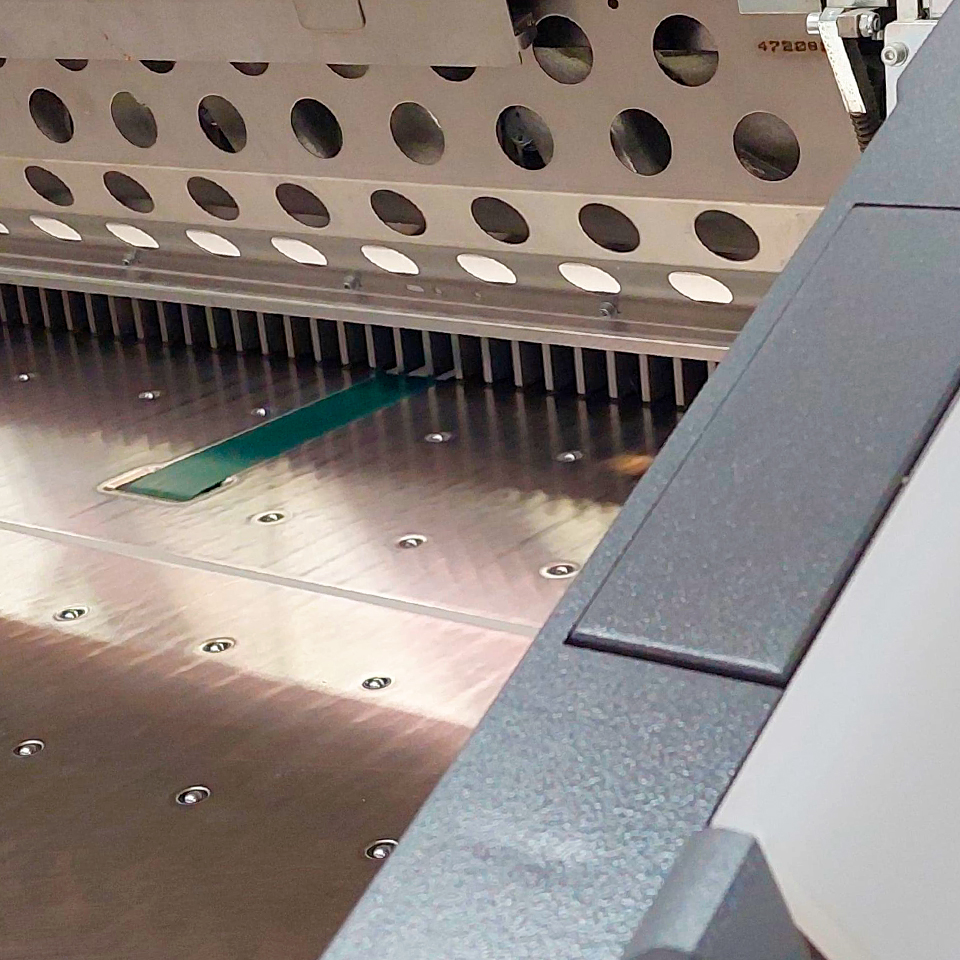

Die Cutting

We perform the cutting on our top Swiss brand automatic machines, which ensure maximum accuracy and reliability. Thanks to the automatic separation of the shape cuttings directly in the machine, we achieve high production efficiency while minimising the risk of errors. These technologies make it possible for us to meet even the most demanding requirements of our customers.

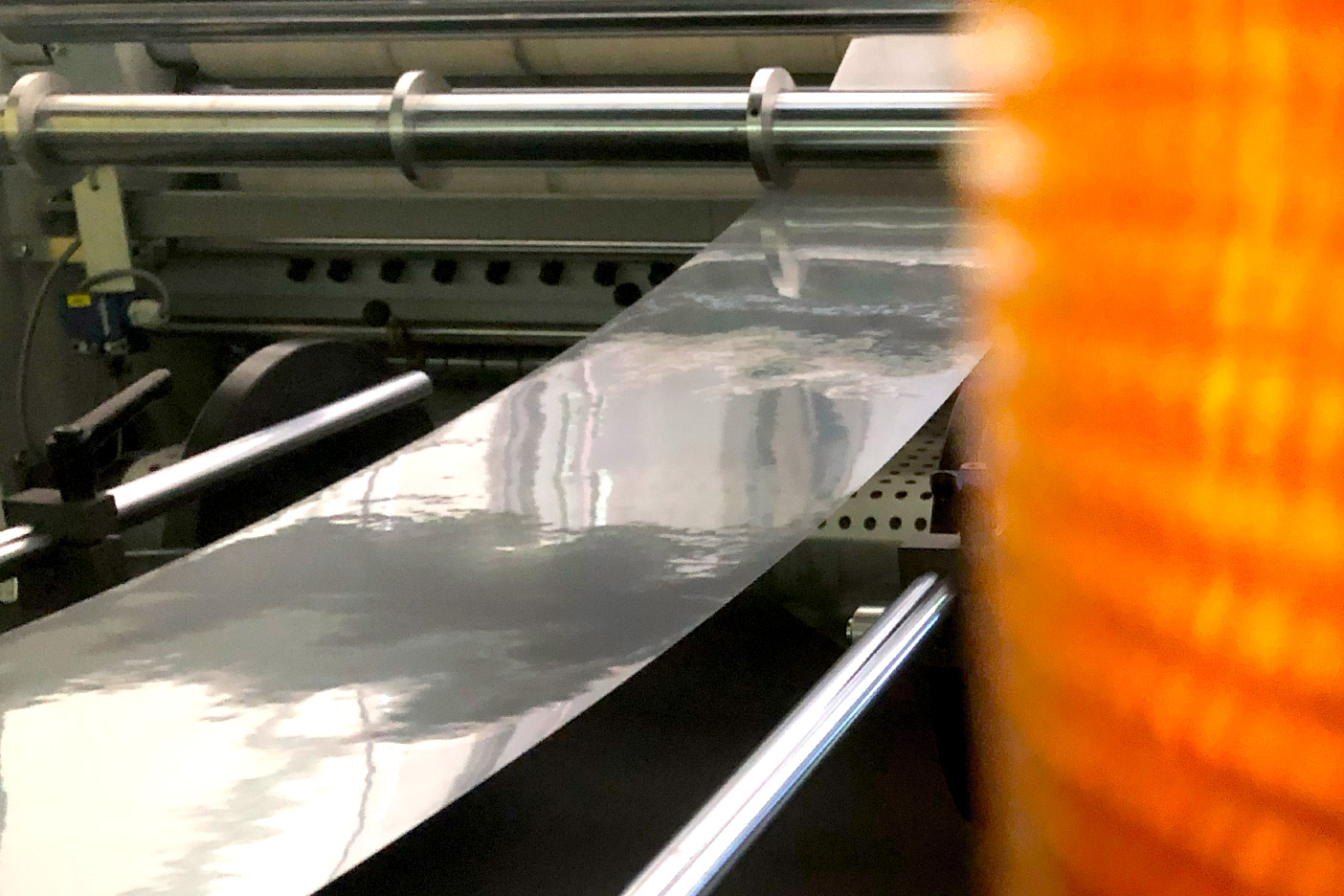

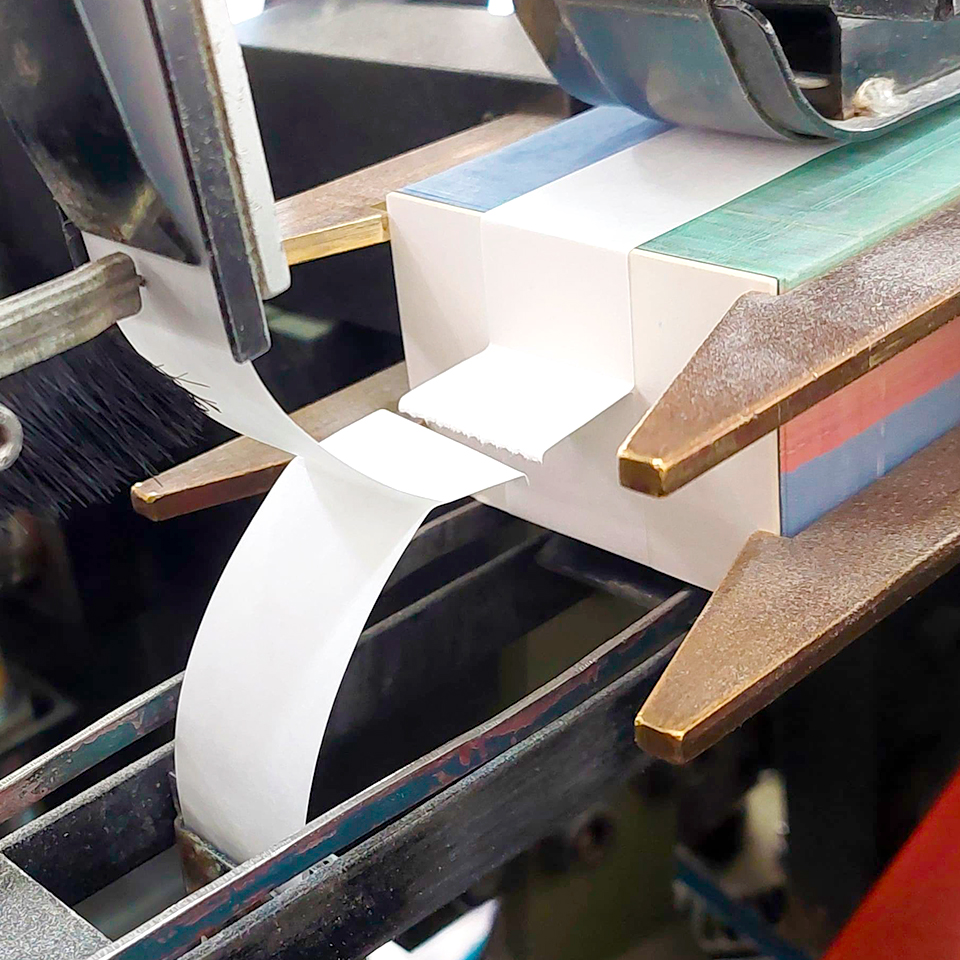

Lamination and windowing

To protect packaging and printed matter intended for long‑term or multiple use, we offer lamination treatment with transparent, coloured and holographic PP and PE films in glossy and matte versions. Lamination not only increases resistance to mechanical damage but also enhances the luxurious visual impression, both to the eye and to the touch.

Another technique involves creating packaging with a transparent 'window' that allows direct inspection of the packaged product without damaging the packaging. This is achieved by cutting a hole in the packaging and then covering it on the inside with PET film to create a transparent but strong window that protects the packaged product.

The manufacture of folders for sanitary towels is a category of its own. By replacing the film with paper, we have achieved easier recycling while maintaining sanitary protection. All these processes are carried out at a single workplace, which allows efficient coordination and the high quality of the final products.

Thermoformed cardboard

Thanks to the unique technology of thermoformed cardboard and using special moulds, we are one of few in the Czech Republic capable of manufacturing round moulded boxes. They are mainly used for processed cheese, but their use also offers other possibilities. In normal operation, we use standardised mould dimensions.

If you are interested in these unique boxes, please contact the sales department to check the options and dimensions, where they will be happy to offer advice and find you the most suitable solution.

Extrusion forming

We mainly use the extrusion forming method to manufacture labels, but also business cards, cards, etc. The labels are suitable for labelling processed cheese, beverage bottles and other products.

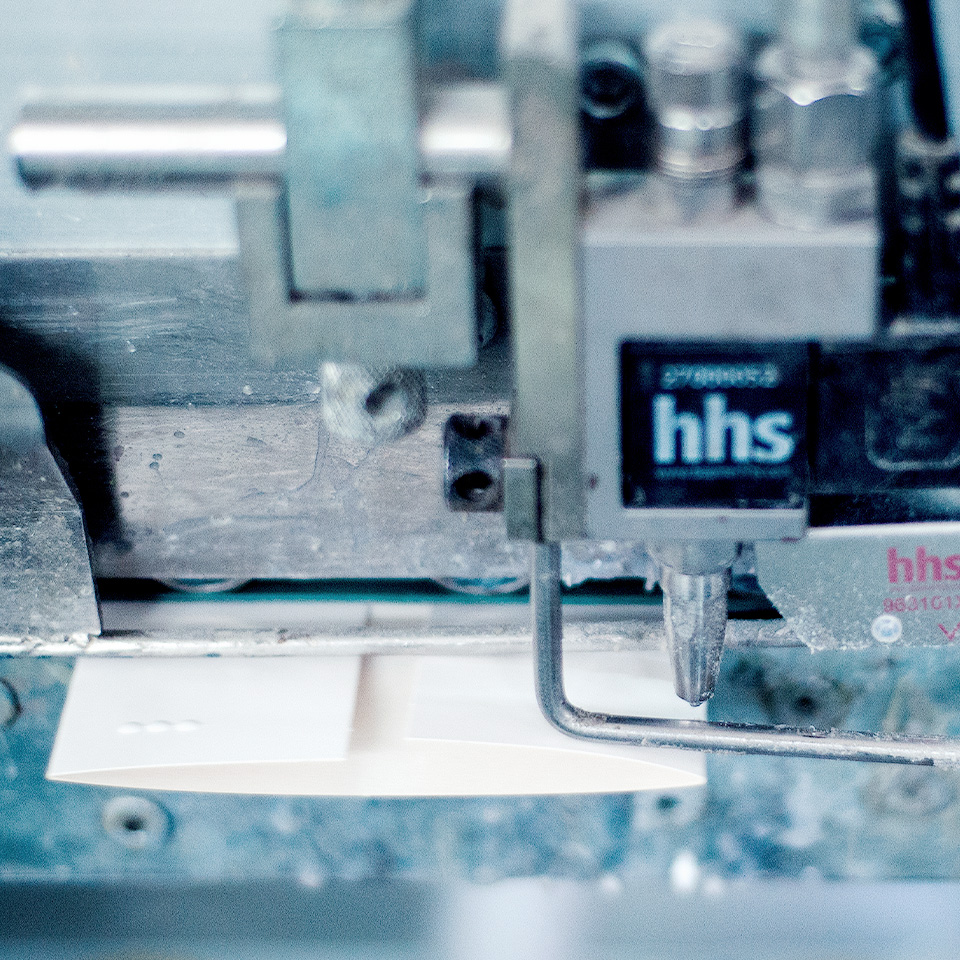

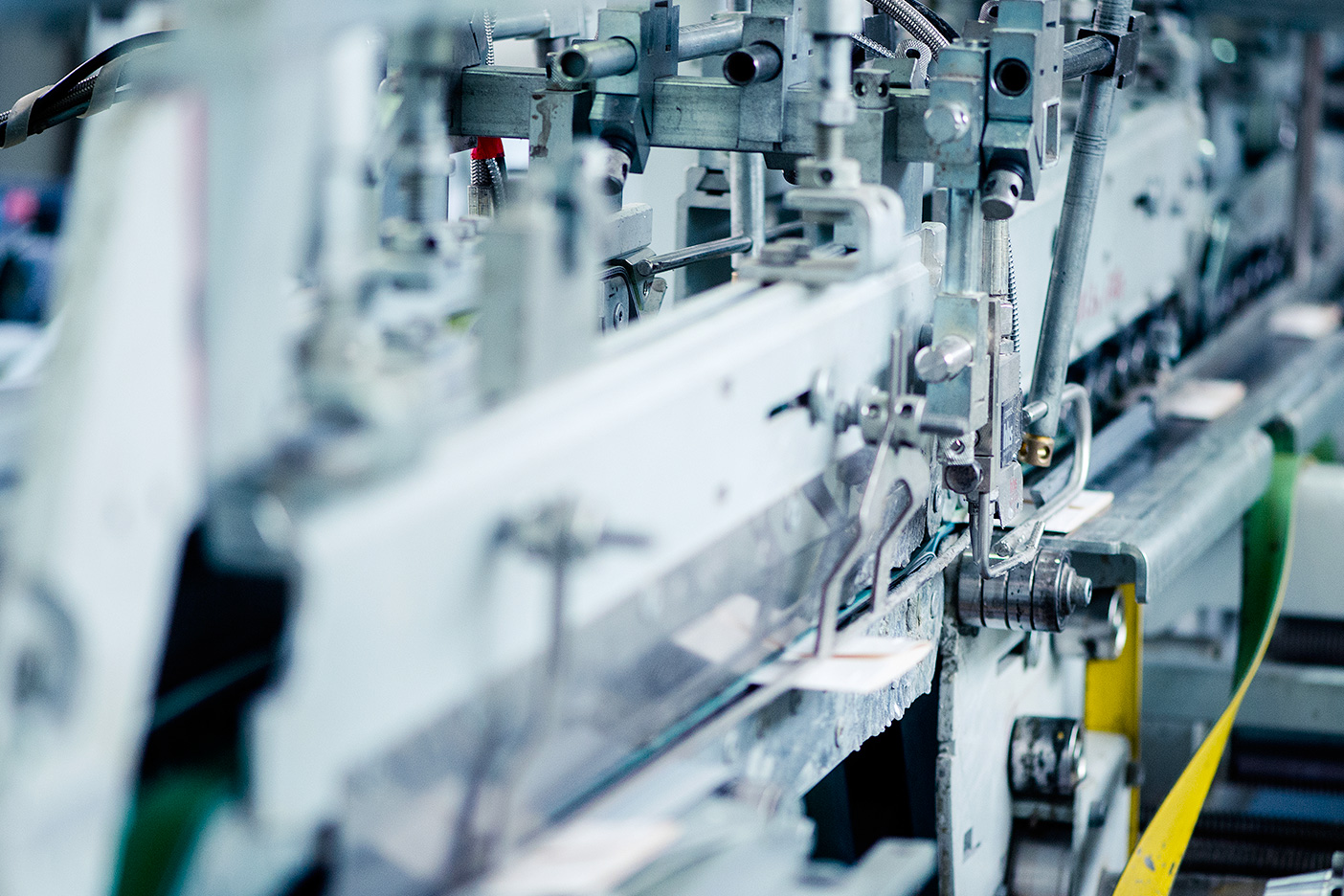

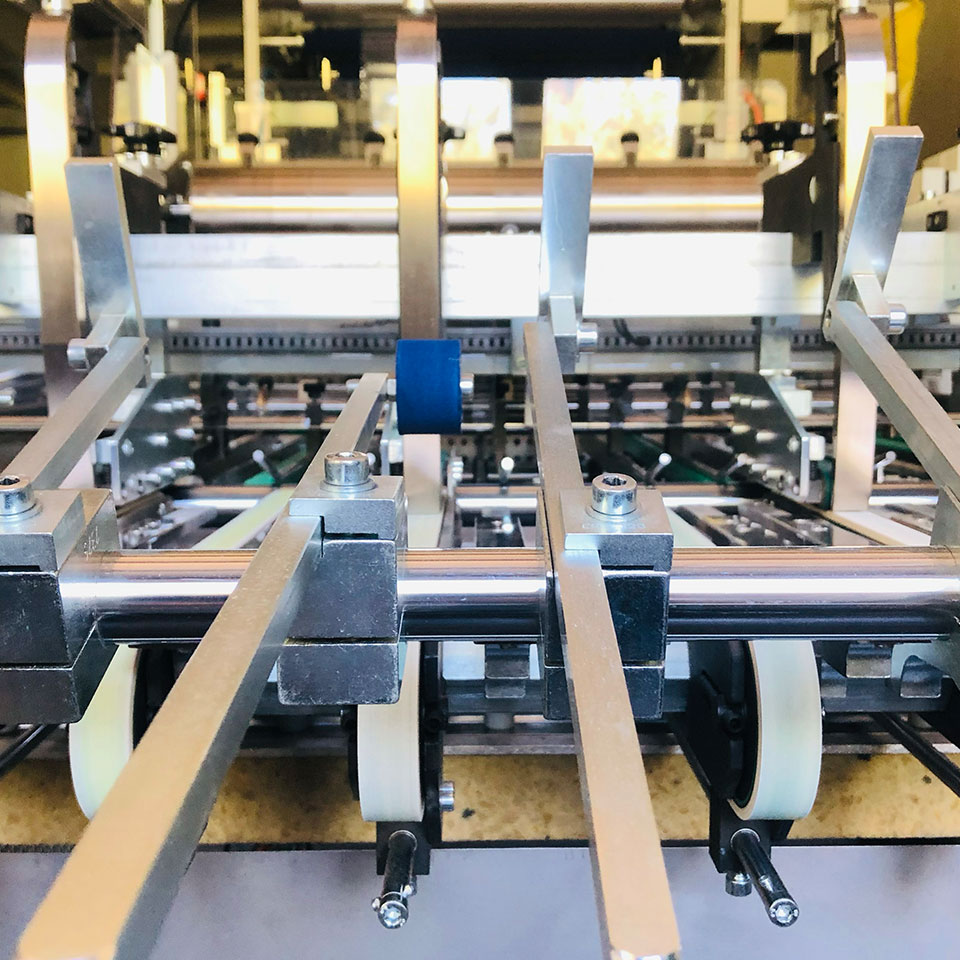

Gluing, folding and assembly

We use modern machines of renowned brands for gluing cut‑out boxes, both standard and atypical (including conical shapes). Thanks to the controlled application of the adhesive on the bonded surfaces, the joints are precise, clean and strong. For increased assembly productivity, we use bar codes that allow simultaneous gluing of multiple product types without the risk of mixing them up.

For some of the more technically demanding jobs, it is sometimes necessary to use human assistance. For these cases, we have our own department of skilled and careful personnel who are able to assemble and glue nearly everything.